Fiber splicing is a critical process in optical fiber communication that involves joining two optical fibers to create a continuous and seamless connection. This connection is essential for establishing an uninterrupted pathway for transmitting optical signals in various applications, including telecommunications and data networks.

Mechanical Splicing

Mechanical splicing is an optical fiber connection method where two fibers are aligned and held together by a mechanical splice. Unlike fusion splicing, there is no melting involved. Instead, the fibers are aligned precisely and held in place with a mechanical splice. While mechanical splicing is simpler and more cost-effective, it may introduce higher signal loss compared to fusion splicing

Fusion Splicing

Fusion splicing involves the permanent joining of two optical fibers by melting and fusing them together. It ensures a low-loss connection and is divided into subtypes, including core alignment and cladding alignment fusion splicing methods. Fusion splicing is known for its reliability and is commonly used in telecommunications and data networks for its minimal signal loss

Importance of Fiber Splicing in Telecommunications

Fiber splicing plays a crucial role in the telecommunications industry for several reasons:

Signal Quality: Fusion splicing ensures low signal loss, maintaining high-quality communication over long distances.

Reliability: Both fusion and mechanical splicing contribute to the reliability of optical fiber connections, reducing the risk of signal interruptions.

Cost-Effectiveness: Mechanical splicing offers a more cost-effective solution for certain applications, making it a viable choice in scenarios where budget constraints exist.

Network Expansion: Fiber splicing facilitates the expansion and maintenance of telecommunication networks by providing a means to connect new fibers seamlessly.

Versatility: The choice between fusion and mechanical splicing allows for versatility in adapting to different network requirements and environments.

Types of Fiber Splicing

Fusion Splicing

1. Process Explained

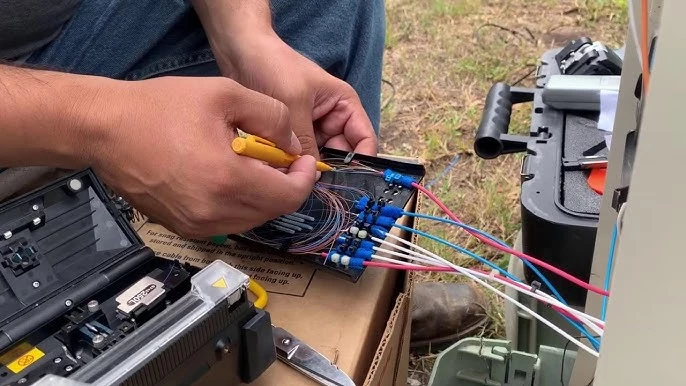

Fusion splicing is a method used to connect two optical fibers by melting or fusing in one another. The process involves the following steps:

- Fiber Stripping: Remove protective coatings from the fiber ends.

- Fiber Cleaving: Cut the fibers with a cleaver to obtain smooth, flat ends.

- Alignment: Precisely align the prepared fiber ends using a fusion splicing machine.

- Fusion: Apply heat to the aligned fibers to melt and fuse them together.

- Cooling: Allow the fused fibers to cool, forming a continuous connection.

- Protection: Place a protective sleeve over the spliced area to ensure durability.

2. Equipment Used

For fusion splicing, the following equipment is commonly used:

- Fusion Splicer: Specialized machine for aligning and fusing fibers.

- Fiber Cleaver: Tool for cutting and preparing fiber ends.

- Protective Sleeves: Sleeves to protect the spliced area.

3. Pros and Cons

Pros

- Less Signal Loss: Fusion splicing results in less signal loss.

- High Reliability: Creates a robust and reliable connection.

- Suitable for Long Distances: Ideal for long-distance communication.

Cons

- Higher Initial Equipment Cost: Fusion splicers are relatively expensive.

- Complex Process: Fusion splicing requires expertise and precision.

Mechanical Splicing

1. Process Explained

Mechanical splicing involves aligning and securing two optical fibers without melting. The process includes:

- Fiber Stripping: Remove protective coatings from the fiber ends.

- Alignment: Precisely align the fiber ends using a mechanical splice device.

- Securing: Mechanically secure the fibers using the splice device.

2. Equipment Used

For mechanical splicing, the primary equipment includes:

- Mechanical Splice Device: Device for aligning and securing fibers.

- Fiber Cleaver: Tool for cutting and preparing fiber ends.

3. Pros and Cons

Pros

- Lower Initial Equipment Cost: Mechanical splicing equipment is more affordable.

- Simplicity: The process is simpler compared to fusion splicing.

Cons

- Higher Signal Loss: Mechanical splicing results in more significant signal loss.

- Less Reliable in Harsh Conditions: Mechanical splices may be less reliable in challenging environmental conditions.

Understanding the characteristics of each splicing method is essential for selecting the appropriate technique based on specific project requirements.

Future Trends in Fiber Splicing Technology

The future of fiber splicing technology is marked by several key trends:

Integration of AI and Automation: The incorporation of artificial intelligence (AI) and automation is expected to enhance the efficiency and precision of fiber splicing processes, leading to faster and more reliable connections.

Increased Bandwidth Demand: As the demand for high bandwidth continues to rise, future fiber splicing technologies will focus on meeting these requirements, ensuring robust connections for data-intensive applications.

Advancements in Fiber Optic Communication Systems: Ongoing developments in fiber optic communication systems, including key technologies, are expected to shape the future landscape of fiber splicing.

Innovative Optical Components: The emergence of new optical components, such as optical couplers and switches, supports evolving communication trends, contributing to the development of all-optical networks (AON).

Technological Advancements: Ongoing technological advancements in fiber splicing are anticipated, ensuring that the technology remains at the forefront of efficient and high-performance connectivity.

Fiber Splicing Loss

Fiber splicing loss refers to the reduction in signal strength that occurs during the process of joining two optical fibers. Several factors contribute to splice loss:

Improper Fiber Alignment: Misalignment during the splicing process can lead to a misalignment loss, causing a reduction in signal strength.

Bending Loss: Inadequate handling of optical fibers, leading to bending beyond the permissible limits, results in bending loss and signal attenuation.

Fusion Splicing Issues: Fusion splicing, while efficient, can introduce losses if not performed accurately. Factors such as improper fusion splicing techniques contribute to splice loss.

Fiber Contamination: Contaminants on the fiber ends during splicing can cause additional losses. Proper cleaning and inspection are crucial to minimize contamination-related losses.

Mismatched Fiber Parameters: Differences in core size, numerical aperture, or other fiber parameters between the spliced fibers can lead to splice loss.

Applications of Fiber Splicing

Fiber splicing, the process of joining two optical fiber cables, finds applications across various industries, enabling seamless and efficient data transmission. Here are some key applications:

Telecommunications: Fiber splicing is fundamental in telecommunications networks, providing reliable and high-bandwidth connections for voice, data, and video transmission over long distances.

Internet Connectivity: Fiber splicing plays a crucial role in establishing and maintaining high-speed internet connections, supporting the increasing demand for fast and stable internet services.

Data Centers: Fiber splicing is essential in data centers where vast amounts of data are processed and transmitted. It ensures efficient communication between servers and storage devices.

Medical Applications: Fiber optics, connected through splicing, are used in medical equipment and procedures such as endoscopy, enabling minimally invasive surgeries and high-resolution imaging.

Military and Aerospace: Fiber splicing is employed in military and aerospace applications for its immunity to electromagnetic interference, ensuring secure and reliable communication.

Industrial Automation: Industries utilize fiber splicing for automation and control systems, benefiting from its resistance to electrical noise and ability to transmit data over long distances.

Broadcasting: Fiber splicing is crucial in broadcasting for transmitting high-definition audio and video signals over long distances with minimal signal degradation.

Oil and Gas Exploration: In harsh environments like oil and gas exploration, fiber splicing ensures robust communication networks, supporting monitoring and control systems.

Sensors and Monitoring: Fiber splicing is used in the deployment of optical sensors for various applications, including structural health monitoring and environmental sensing.

Research and Development: Fiber splicing is employed in laboratories and research facilities for creating custom optical setups and experimental configurations.

Fiber Splicing Best Practices

Fiber splicing is a critical process in ensuring reliable and efficient optical communication. Adhering to best practices is essential for successful fiber splicing. Here are some key best practices:

Proper Fiber Preparation:

- Ensure cleanliness and proper stripping of fiber ends to prevent contaminants that can impact signal quality.

Precise Fiber Cleaving:

- Use high-quality cleaving tools for precise fiber ends, minimizing splice loss and optimizing light transmission.

Alignment and Inspection:

- Employ fusion splicers with advanced alignment systems to achieve accurate core alignment.

- Regularly inspect and clean fusion splicer electrodes for optimal performance.

Environmental Considerations:

- Perform splicing in controlled environments to minimize the impact of temperature and humidity on fiber performance.

Quality Splicing Equipment:

- Invest in reliable fusion splicers and mechanical splicing equipment to ensure consistent and durable splices.

Fiber Slack Management:

- Properly manage fiber slack to avoid excess stress on splices, ensuring long-term reliability.

Documentation:

- Maintain detailed documentation of splicing procedures, including splice locations and parameters, for troubleshooting and future maintenance.

Training and Certification:

- Ensure technicians are trained and certified in fiber splicing techniques to guarantee proficiency and adherence to industry standards.

Testing and Verification:

- Perform thorough testing using optical time-domain reflectometers (OTDR) and power meters to verify splice performance and identify any issues.

Regular Maintenance:

- Implement a regular maintenance schedule for splicing equipment and tools to prevent degradation and ensure consistent performance.

Testing and Estimation

Testing and estimation are crucial aspects of fiber optic splicing to ensure the reliability and performance of optical networks. Here are key considerations:

Loss Budget Calculation:

- Determine allowable power loss in the network by calculating the loss budget, considering factors like fiber length, splices, and connectors.

Fiber Loss and Distance Estimates:

- Calculate total link loss through a fiber optic link, factoring in fiber length, splices, and connectors for accurate distance estimates.

Loss Expectations:

- Understand typical component losses for fibers, splices, and connectors to set realistic expectations for testing outcomes.

Quality Standards and Verification:

- Enhance estimation accuracy by applying industry quality standards, and verify and test spliced or repaired fibers to ensure compliance.

Testing Levels:

- Conduct various levels of testing, starting with a quick go/no-go test by the splicing machine. This initial test determines the viability of the splice

Industry Outlook and Career Opportunities of Fiber Splicing

The field of fiber optic splicing presents promising career opportunities, driven by the increasing demand for high-speed data transmission. Here’s a snapshot of the industry outlook and career prospects:

Growing Job Market:

- The job market for fiber optic splicing is expanding, with significant demand for professionals skilled in cable installation and maintenance services.

Lucrative Career Choice:

- Fiber optic splicing is considered a fulfilling and potentially lucrative career path, offering opportunities for designing, installing, and maintaining fiber optic networks.

Job Outlook and Growth:

- The job outlook for fiber optic splicers is positive, with projected growth in the industry. Automation and technological advancements, such as automated splicing, contribute to the sector’s vitality.

Future Trends and Technology:

- Future trends in fiber splicing technology include automation, streamlining operations, reducing maintenance costs, and improving network performance.

Revolutionizing Telecommunications:

- Fiber optics, with its high-speed data transmission capabilities, has revolutionized the telecommunications industry. The thin strands of fiber optic cables play a crucial role in the industry’s evolution.

Market Landscape and Growth:

- The fiber optic connectivity market is poised for growth, with business strategies focused on development trends and insights into the market landscape.

Considering the rapid advancements in telecommunications and the critical role of high-speed data transmission in our connected world, exploring a career in fiber splicing can be both rewarding and impactful. As technology continues to evolve, the demand for skilled fiber optic technicians and splicers is on the rise. The industry offers diverse opportunities, from designing and installing fiber optic networks to ensuring their efficient maintenance. Engaging in specialized training programs, such as those provided by the Fiber Optic Association, can boost your expertise and career prospects.

The field not only promises financial stability but also the satisfaction of contributing to the backbone of modern communication systems. With the potential for growth and the continuous expansion of the telecommunications sector, choosing a career in fiber splicing opens doors to a dynamic and fulfilling professional journey.